If you read the technology news of the day, it looks like everybody is talking very seriously about AI. The awareness this creates is excellent, but it’s even better when companies from more traditional industries take up the task to experiment and find ways to apply AI into their daily operations. Companies from medical & health industries, metallurgy are finding ways to use AI and regain a competitive edge.

We’ve participated in Digital Metals AI Hackathon organized in Vienna by Pioneers.io and accepted the challenge to build an exciting new solution for AI-enabled measurement of metal parts. The goal of the hackathon is to generate the best ideas and create new solutions in a rapid prototyping format.

Voestalpine and Primetals were the hosts of the event. By bringing together industry leaders and the best technology leaders from the startup world, the two industrial companies hoped to solve specific real-life challenges and identify potential collaboration opportunities for the future.

There were four predefined challenges that the participating startups need to address. We took part in one of the cases of Voestalpine: Measuring Steel Pieces with a mobile app. The Metals Division of Voestalpine, the market leader for tool steel, is focused on producing and processing high-performance materials. High-speed steel, valve steel, as well as powder materials, nickel-based alloys, titanium, and components, are produced using additive manufacturing technologies.

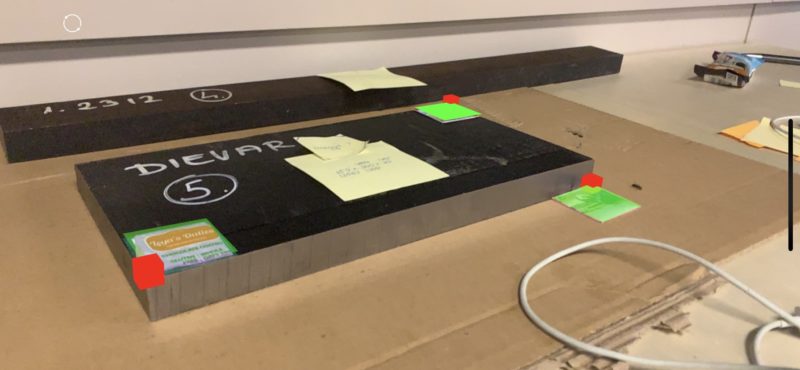

The goal of the challenge is to develop a mobile app that uses the camera for dimension-measuring for steel parts. The app has to be able to measure the three dimensions of rectangular Voestalpine steel pieces using a photo or video. The use of an app will make the process more effective and less prone to errors.

The way measurements are currently conducted is by measuring three dimensions with a tape measure and manually typing them in via a keyboard. It turns out to be time-consuming, leading to mistakes and causing frustration. The metal pieces that need to be measured are quite heavy and impossible to be moved around for better access or more convenient measurements.

The atmosphere at the event was excellent, with funny ice-breakers, cozy, working areas, and mentors form the metal industry companies present at all times.

We were able to build an impressive rectangular steel piece measuring MVP using the Apple AR Kit, apply computer vision and computational geometry know-how to recognize markers in 3D space in less than a day.

As demonstrated in the short video below, once the markers (we used parts of protein bars packaging as a set of improvised markers ;)) are positioned around the steel piece, the only thing the operator needs to do is to point the camera to each of them until it’s detected and then move to the next one. Once all three markers have been visible (sequentially, not needed to be at the same time as it’s not practical for long pieces), the system suggests the dimensions of the items in millimeters.Of course, the operator may go in manual mode and adjust the measurement if needed.

This whole prototype was built in less than a day after we found out the first evening that a solution trying to have all markers visible in a single shot won’t be practical for a long piece.

Our solution turned out to be promising. Some of the participants and judges couldn’t believe it might work even without full visibility of the three markers.

We are exploring more practical applications of image recognition for smart factories. We believe we have just scratched the surface when it comes to automation and augmentations possible with current AI technologies.

Below is a video demonstrating how our visual search technology can be used for recognizing different machine parts, something of enormous value when some repairing or replacement is needed, and there is a vast catalog of possible inventory.